1.Mobile Toilet

HDPE Toilet

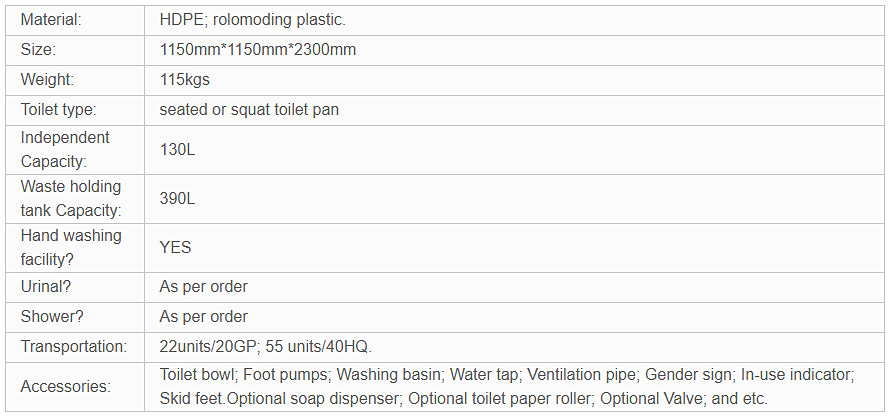

●Portable Toilet also called HDPE Toilet, Plastic Site Toilet, Movable Site Toilet, Site Chemical Toilets, Modular Portable Toilets, Red Economic Toilets and Site Toilets, refer to toilet stalls that are made from HDPE panels & installed with ventilation, door, electrics, plumbing, sanitary,sometimes also included clean water tanks & waste tanks. ●Such portable toilets are commonly used in construction sites, oil sites, mining sites as workers' toilets, site showers, also used for solider camps, government projects & school projects as temporary site toilets & bathrooms.

1.Movable, thus avoiding the waste of resources caused by house demolition. 2.The processing method is various, and the appropriate processing method can be adopted according to the limitation of the use environment. 3.The floor space is small. Compared with the traditional toilets, the mobile toilets have greatly saved the land area, which just caters to the current situation of land shortage! 4.Beautiful and generous, on the basis of ensuring practicality, pay attention to the importance of beauty, and become a scenic spot of tourist attractions and park communities! 5. Significantly save manpower, material and financial resources in the construction. The construction of traditional toilets usually needs to be selected, purchased, constructed, completed, put into use, etc.1. Portable Toilets flushing has a spring valve, can isolate the smell into the toilet. The roof is made of HDPE with two layers of thickening and natural lighting to ensure that the interior of the toilet is bright. 2.The color is diverse, the conventional red, yellow and blue. User-friendly configuration, such as coat hooks, vanity mirrors, etc. 3.Movable Toilets are gender signs, automatic door closer and padlocks, which can be locked when not in use. 4.HDPE Mobile Portable Toilet have nice appearance, a wide range of use, such as outdoor wedding scenes, marathon events, convention centers, commercial areas, tourist attractions, subway stations, construction sites.

1.Movable, thus avoiding the waste of resources caused by house demolition. 2.The processing method is various, and the appropriate processing method can be adopted according to the limitation of the use environment. 3.The floor space is small. Compared with the traditional toilets, the mobile toilets have greatly saved the land area, which just caters to the current situation of land shortage! 4.Beautiful and generous, on the basis of ensuring practicality, pay attention to the importance of beauty, and become a scenic spot of tourist attractions and park communities! 5. Significantly save manpower, material and financial resources in the construction. The construction of traditional toilets usually needs to be selected, purchased, constructed, completed, put into use, etc.1. Portable Toilets flushing has a spring valve, can isolate the smell into the toilet. The roof is made of HDPE with two layers of thickening and natural lighting to ensure that the interior of the toilet is bright. 2.The color is diverse, the conventional red, yellow and blue. User-friendly configuration, such as coat hooks, vanity mirrors, etc. 3.Movable Toilets are gender signs, automatic door closer and padlocks, which can be locked when not in use. 4.HDPE Mobile Portable Toilet have nice appearance, a wide range of use, such as outdoor wedding scenes, marathon events, convention centers, commercial areas, tourist attractions, subway stations, construction sites.

1. All products are designed to be shipped disassembly. 2. Packing method is bubble paper with plastic film. 3. One 20ft container can fit 30 disassembled units; one 40ft container can fit 60 units; one 40HQ container can fit 70 units.

1. All products are designed to be shipped disassembly. 2. Packing method is bubble paper with plastic film. 3. One 20ft container can fit 30 disassembled units; one 40ft container can fit 60 units; one 40HQ container can fit 70 units.